Why use Nylon material in sports brace?

Table of Contents

What is Nylon Fabric?

Putting in simple language, Nylon is the term used to refer to a group of synthetic polymers. They are used for making different types of apparel and consumer goods. Contrary to organic or semi-organic fibers, nylon fibers are entirely artificial. They do not have any organic stuff.

They first came into existence during world war II. Then, it was mainly used for making parachutes. Following this, they got started using it as an alternative to silk. At the time of this war, 80 % of all textile was made from cotton in the United States. By 1945 however, synthetic fibers started getting used and constituted as much as 25 % of the total textile market share. The rapid growth of demand for nylon fabric resulted from the shortage of traditional dress materials. Therefore, they included cotton and silk primarily. Therefore, dressmakers made dresses from parachute material, which were repurposed, made from nylon fabric.

Once the war ended, textile manufacturers were looking for new ways to market the latest types of nylon fabrics, and they became more popular.With the shortage of usual dress materials, Nylon started getting used to making ladies’ stockings and lingerie.

DuPont was the company marketing it early, and Nylon’s initial name underwent several changes. Initially, the company planned to name it “no run .”It was done to the perceived ability of the nylon fabric to resist “runs .”It is when used in materials. But it was soon discovered the fabric is subject to runs. So, the name was changed to “neuron .”But even after this, there were other changes made to the material.

History of Nylon

In the initial days, some significant drawbacks we have seen to Nylon, like the fabric’s lack of moisture-wicking properties. The challenges were so much that some even considered it a failed experiment. However, it was during this time some innovations were introduced. As a result, mixing with other materials like polyester, spandex, or cotton became popular. It was done to eliminate the drawbacks of the nylon fabric. Over the years, the 1940s & 50s got famous, but there was a steady drop in popularity, especially after the 1970s.

Out of the many reasons the popularity of the nylon fabric declined is its hazardous environmental impact. With the rapidly deteriorating environmental conditions, people have become more and more people became environmental conscious. It meant they sought more environmentally friendly fabrics. Thus, they started using fabrics made from organic raw materials. Therefore, it is another factor that affects the demand for nylon fabric negatively.

As of 2008, it was seen that only about 12 % of the total global synthetic fiber production consists of Nylon. It clearly showed a sharp decline in the use of nylon fabric to manufacture garments.

The use of Nylon for consumer garments has indeed seen a decline. But it is being seen that for industrial and scientific purposes; Nylon is still widely used. Moreover, they are now being used to produce plastic, making them durable and versatile.

How is Nylon made?

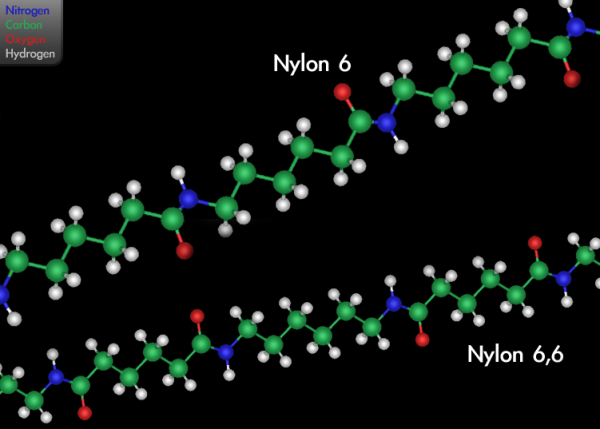

Nylon is a fabric that is not organic in any way. It is wholly produced artificially. Many steps are used for the production of nylon fabric. The production process of the Nylon may vary. It can vary depending on the type of Nylon to be produced. For each class, the production process may differ. But the production process broadly remains the same.

If you wonder how is the nylon fabric made, you need to note it is made from a long chain of carbon-based molecules. These are called monomers. Different nylon types exist, but most are derived from polyamide monomers. These are extracted from crude oil.

The monomer, also known as hexamethylenediamine, is used for nylon production. Sometimes this substance is called diamine acid.

For making Nylon, the acid is made to react with adipic acid. Then PA 6,6 is the polymer used to make the nylon fabric. They are derived from a nylon salt, heated, and made to form something molten. The molten substance goes through specific processes, and fibers are created. They are again stretched to increase their strength and elasticity. Once this is done, they are wound onto another spool. It is done through a process called drawing. Finally, these are arranged into a parallel structure, after which they are ready to be spun into garments and other types of fibers. The final step, which is the finishing, involves the coloring of the nylon fabric. The nylon fabric is finally dyed to produce the desired material as the end product.

How are Nylon fabrics used?

Initially, Nylon was mainly marketed as an alternative to silk stockings. Before the development of Nylon, silk was primarily used for making stockings. However, silk was costly, and Nylon being much cheaper, was the immediate alternative. Though a lot of the initial hype was created by DuPont, it failed to live up to all the expectations in many ways. But it was a prevalent stocking material. It was more so amongst the professional and domestic women. It was widely used despite limitations as a stocking material until the latter half of the 20th Century. What is also interesting is even during current timings, for women’s stockings, Nylon continues to be one of the most widely used materials. It is also used for yoga pants and other types of women’s bottom wear.

Even in the case of specific sportswear, it is considered inferior to other semi-organic synthetic fibers.

Despite the mentioned drawbacks, to increase the elasticity and lightness of the fabric, some sportswear manufacturers use nylon fabric and mix it with other materials.

Thus, though the drawbacks exist, the use of nylon fabric continues to remain quite prevalent.

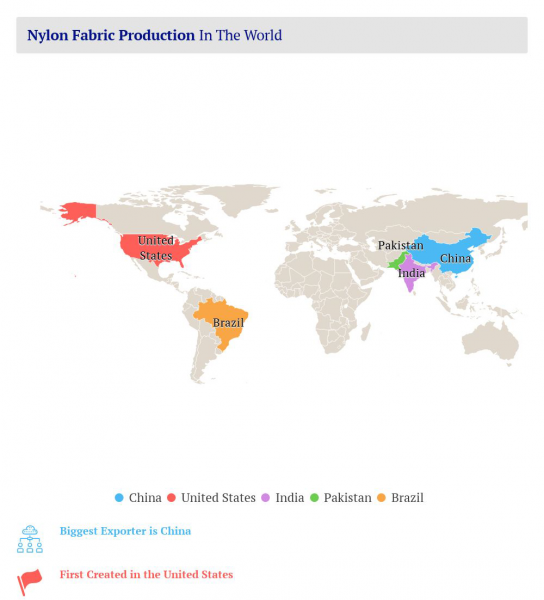

Where is the Nylon fabric produced?

In the initial days, the nylon fabric was first manufactured by Dupont Corporation in the US. So the fabric’s production was also mainly restricted to the US. However, gradually towards the second half of the 20th Century, as the benefits of the material got recognized in the other parts of the world, other nations too started producing it. In the 1980s, China too became a manufacturing hub for nylon fabric. Production is also picking up in other countries like India, Pakistan, and Indonesia.

How much does the fabric cost?

The primary benefit of the nylon fabric is its low cost. Since silk was expensive, it was mainly developed to replace it at a lower price. During such times, in the initial years, the cost of Nylon too was high. But over the years, the cost of Nylon has fallen drastically, thereby making of very popular all across the globe.

What is also very encouraging to know is when mixed with other fabrics, the cost falls even more. At the same time, some of the drawbacks of the materials can be eliminated to a certain extent if the same is mixed with other materials. If you check in recent times, the price of nylon and nylon mixed fabrics has become very low indeed.

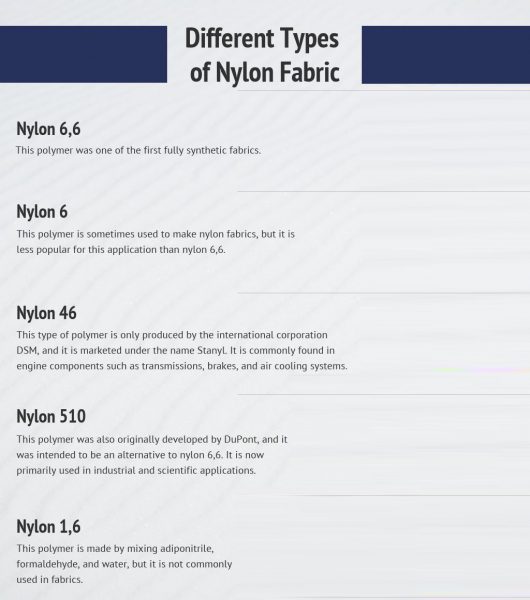

What are the different types of nylon fabrics?

As has already been discussed, Nylon is a fabric that is not natural and is manufactured artificially. Therefore, the types of nylon fabric are many. Much of the kinds of nylon material depend on the chemical composition of the fabric. Let us take a look at some of the more common ones:

Nylon 6,6

You will find that nylon 6,6 was one of the first types of nylon fabrics manufactured. The nylon 6,6 is manufactured by mixing hexamethylenediamine with a dicarboxylic acid. Once the mixture is made, they are heated and melted for the formation of fibers or crystallized mainly for purification.

Nylon 6

It is yet another nylon type that is quite common. However, in terms of popularity, it is less than nylon 6,6, which is by far the most popular type of Nylon that is now used.

Nylon 46

The international corporation DSM produces the nylon 46 polymer. The marketing of this type of Nylon is done under the name Stanyl. This kind of Nylon is usually not used in fabrics and is also not environmentally safe. But it is generally for making different types of engine components. The components include brakes, air cooling systems, etc.

Nylon 510

The nylon 510 was initially developed by Dupont, and it was done mainly to serve as a replacement for the more popular nylon 6,6. But since the production costs of these nylon polymers became very high, their mass production became almost impossible. Therefore, at present, since mass production is not possible owing to the high costs of production, its use is mainly restricted to industrial and scientific use only.

Nylon 1.6

It is the last type of Nylon that we will discuss. The production of this type of nylon polymer is made by combining adiponitrile with formaldehyde along with water. However, this type of Nylon is not usually used in fabrics.

So, we can see that the types of Nylon are diverse, each having its specific purpose.

How does the nylon fabric impact the environment?

You will be aware of the risks of rapidly deteriorating environmental conditions. Much of this is happening due to the increase in pollution, So the environmental worries continue to haunt many of us. Now with more and more people becoming more environmentally conscious, people are seeking everything ecologically friendly.

The bad news with nylon fabrics is that it harms the environment.

The main reason Nylon adversely affects the environment is one of the primary inputs known as hexamethylenediamine. It is damaging to the environment. It is the main constituent of the most popular nylon fabric types. The substance is something that is derived from crude oil.

It is now a well-known fact that both the acquisition and the use of fossil fuels adversely affect our environment. All the processes like drilling, fracking, and other methods used for crude oil production adversely affect the environment. Besides, crude oil is not a sustainable resource. Therefore, it becomes necessary to expand the global oil industry.

A great deal of energy is required to produce nylon fabrics. Burning these fuels has a very negative impact on our environment. Thus, the very production process of nylon fibers has a substantial negative impact on our environment. Apart from this, many of the wastes generated from nylon production also negatively impact the environment. Many of these waste materials are much more harmful to our health and the environment. Besides, nylon fibers are all artificially manufactured. They are in no way biodegradable and thus has a very adverse impact on the environment.

Even worse, there is no specific way to mitigate the many environmental hazards that the production and the use of nylon fabrics have. The only way that you can minimize the harmful impact is by having them disposed of properly. In addition, specific polymers used in the production of nylon fabrics may even be toxic by nature. But there is only little that we can do to reduce the adverse effects of nylon fabric on the environment.

Though the benefits of the nylon fabric are indeed many, there are many drawbacks, too it has. One of its significant drawbacks is it environmentally hazardous.

Nylon fabric certifications

Regarding fabrics or, for that matter, any industry, certifications can go a long way to give authenticity. If you check the nylon fabric market, you will find many tests can be performed. Unfortunately, there are no certifications available for nylon fabrics. You will realize that since the material is produced artificially, there is no way it can be certified as natural or organic. The scope for such certifications is in no way possible. But that is the way it is. Despite the advantages, like the cheap cost of the fabric, the lack of proper certifications is a drawback of the nylon fabric.

Advantages:

1. Resilient

Nylon is one of the most stretchy materials of all fabrics. In fact, nylon is often blended with other fabrics because of its elasticity. For example, nylon bedding resists the stretching and pulling of rough sleepers. This feature is also reflected in nylon-based tights and stockings, which are particularly valued in the market.

2. Durable

Nylon has excellent tensile strength and single fiber strength. In terms of cleaning, we recommend that you clean the nylon cloth at a lower temperature, which can well avoid the deformation of the fabric.

3. It is very versatile

Nylon’s versatility as a chemically produced material is critical to its success. Many different features can be embedded into nylon fibers during the manufacturing process. Nylon is also easily dyed, making it an integral part of many plastic products today.

4. Strong hygroscopicity

As a synthetic fiber, nylon is somewhat rare in its hygroscopic properties. This improves the ease of cleaning and washability of nylon. Additionally, this property makes nylon more breathable than other synthetic equivalents such as polyester.

5. Anti-static

Nylon is an antistatic material. This feature helps in particularly dry environments. In winter, for example, static electricity can be an uncomfortable nuance. That’s why nylon is great bedding in cold, dry winters.

6. The product is very reliable

Products made from nylon are lightweight and relatively inexpensive. When it comes to nylon products, you don’t have to worry about excessive wear and tear, and when properly cared for, this material can reliably deliver quality and function.

7. The fabric is stain-resistant

If you have special requirements for cleanliness, nylon fiber is your best choice. They can be easily cleaned and cleaned. Any liquid or oily spills are easily removed with a quick wash.

Disadvantages:

1. Nylon is an expensive synthetic fiber

As a synthetic fiber, nylon is expensive. Even though it’s less expensive than other high-quality eco-friendly alternatives, it’s still more expensive than other synthetic fabrics. If you’re looking for a quality synthetic fabric, nylon is a great choice.

2. Nylon production is not environmentally friendly

Nylon is a synthetic fiber produced using complex chemical reactions. A lot of chemical fertilizers are produced during its manufacture, which has some very far-reaching environmental impacts. In developing countries such as South America or Southeast Asia, the production of synthetic fibers causes severe chemical emissions and pollution to natural ecosystems.

The production of nylon also seriously pollutes the air. Toxic gases are generated during production, and these gases must be filtered out of the manufacturing plant. Because they are considered harmful to health.

3. Nylon melts and burns

A point of special attention is the low burning and melting point of nylon. Its thermoplastic nature causes nylon to melt when ignited and emit toxic fumes. So usually experts advise against wearing or using nylon when making barbecues, campfires or gas cooking.

Talk to our experts about the product you want to manufacture, and we’ll help you with all you need.

FAQ

Is nylon OK for skin?

It is durable and not very expensive to produce, which is why it’s popular. At the same time, nylon is not the best choice to wear on your bare skin

What is nylon made out of?

Nylons are a family of materials called polyamides, made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure, heated environment.

Is nylon natural material?

Nylon is the name of a family of synthetic polymers that are commonly used to make a variety of different types of apparel and consumer goods.