Why use Spandex material in sports brace?

Table of Contents

What is the Spandex fabric?

Regarding the latest fabric trends, you might have come across spandex. But, if you wonder what it is about, let us see it and explore its various aspects.

Let us begin by understanding the Spandex fabric. Putting it simply, spandex is a synthetic fabric that has a very high elasticity.

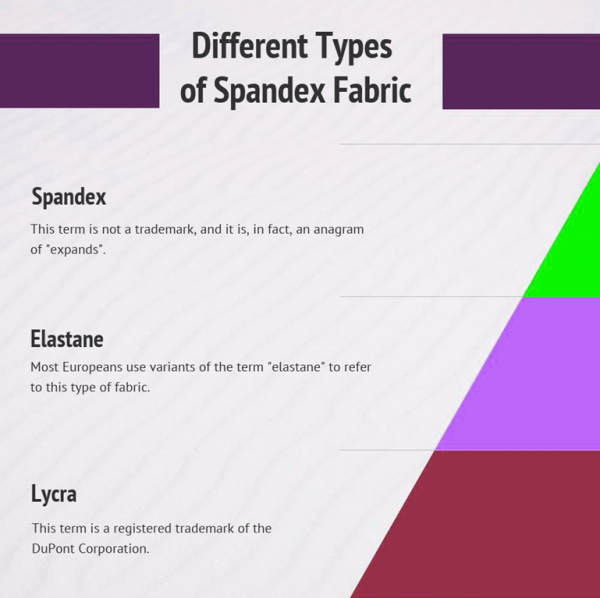

It is often seen that many people assume that spandex is a brand name. But it is not so.

Spandex is a fabric material that is made from long-chained polymers, which is known as polyurethane. It is produced when polyester is made to react with diisocyanate. The spandex polymer thereby created is converted into fiber. It is done by using a dry spinning technique.

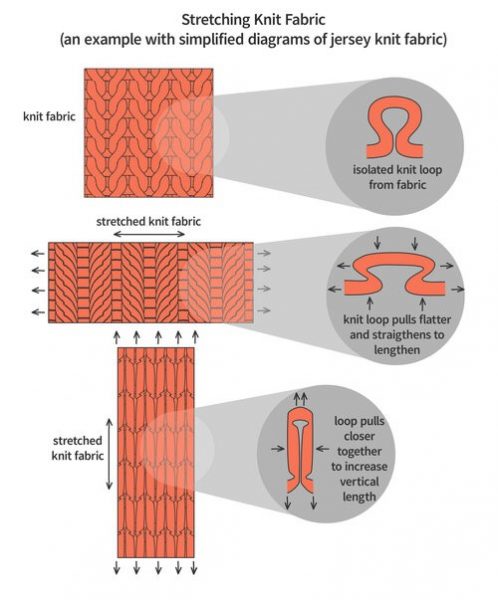

The unique feature of the spandex fabric is it has a lot of elasticity, which is why it can stretch as much as 5 to 8 times its standard size.

The fabric has a wide range of uses, but out of the many, it’s mainly used in form-fitting consumer apparel. You also need to be aware that it is not usually directly used in garments. But it instead is used in small quantities of fabrics woven into other synthetic and semi-synthetic ones. Sometimes they are also used with organic fibers.

The early origins of spandex

The spandex fabric came into existence only recently. It was first developed in 1937 by I G Farben, a German textile engineer. The material he used for the fabric was polyurethane, which was developed towards the end of the second world war. He worked for DuPont at the time, which was then the undisputed leader of synthetic textiles.

During the time, the corporation sought to create a new type of polymer which had high elasticity. The fabric was successfully developed then, and the brand name used for this fabric was called Lycra.

Much on the lines of similar polymers, this fabric is developed by repeating chains of monomers held together with the help of acid. When this particular synthetic material was being developed, it was also recognized it was highly heat resistant. However, it was much contrary to other synthetic materials, including nylon and polyesters. They are improved by combining them with the spandex fabric to make them more heat resistant.

What made it instantly famous?

Spandex became an instant hit because it could be easily stretched without causing any damage. Due to this, the fabric continues to be very popular and sought-after even in the current times when consumers have so many options and choices. It is also interesting to note that it is improbable that the fabric’s popularity will dwindle in the recent future.

But despite its popularity, the one big drawback of the fabric is it has a detrimental impact on our fast-deteriorating environment. It is all the more concerning with more and more people becoming environmentally conscious and thus seeking more environmentally friendly things, including fabrics.

How is the material made?

Like all other synthetic materials, the spandex is also entirely artificially made and has no organic component.

All this material is produced artificially in the laboratory under specific conditions and stimuli. Over the years, many methods have, of course, created this artificial fabric. However, it is to be noted that some of the materials are more efficient than others.

As the production process for producing this fabric is getting more developed and advanced, several of its production processes are getting eliminated. These include various methods like reaction spinning and even wet spinning.

You also need to note that despite the variety of the production processes, nearly 95 % of all Spandex production is done through a process known as solution dry spinning. Let us see how it is made under this process in further detail.

The most widely used spandex production process

At the beginning of the spandex fabric production process, a substance called macro glycol is combined with a diisocyanate monomer. It is done at a particular temperature and pressure level. While production is on you, you need to note that the temperature and pressure conditions match the exact settings for getting the best results. The ratio of the mixture is to be made the ratio of 2:1.

Once this is done under the right conditions, a substance called a prepolymer is formed. The prepolymer so produced is used in the remaining production process. After this, the prepolymer is exposed to diamine acid, and the chain extrusion reaction is initiated. It is a chemical process.

What is produced as a result is highly viscous. The viscous resultant is then diluted with a solvent to enable it to move on to the following production process. After a sufficient amount of dilution, it becomes thin, and then it is loaded onto the fiber production cell, which is also called the cylindrical production cell. Inside this cell, the final product gets produced, which are strands of the spandex fabric. The final stage is when the liquid state residue is exposed to a heated solvent gas and nitrogen, which converts the liquid state into the final solid-state of the spandex fabric.

How is Spandex fabric used?

Spandex is used for different purposes, ranging from consumer to industrial applications; however, they are mainly used in those applications where high elasticity is desired. It has been prevalent since the early times since it was created. Its enormous popularity continues even in the present day. It is being used in different types of garments and by consumers all across the globe.

The one thing which needs to be noted is they are pretty costly and generally used by professionals.

It is often mixed with other fabrics.

It is seen that when mixed with other garments like cotton, the resultant garment becomes much more elastic. They are also often combined with polyester to make them stretchier. The one important feature of the spandex fabric is that it can stretch up to eight times its original size.

Most common use

Regarding garments, the most common use of spandex is in producing different types of underwear for both men and women. It is not present in the main fabric of the underwear but is used primarily for the waistband. Due to its high elasticity feature, spandex is used in almost every type of stretch garment.

They are also used in the making of cotton and woolen socks. Using this fabric enables the socks to stay longer on their feet.

In the case of sportswear, this fabric is commonly used. The main reason for this is in the case of sportswear; it becomes essential for the material to stay close to the skin. Thus, you will notice it is often used for making swimwear, bicycling wear, and all types of clothing that are part of competitive sports. So, everything is put together, and you will find wide use of spandex in the garment sector as a whole and more so in the case of sportswear.

Industrial applications of spandex

Apart from consumer use, spandex can be used in industrial applications.

If you know where it is used in industrial applications, you will see that the fabric is used in the film industry. It is used here to make motion capture suits. The actors wear these suits while shooting in front of a large green screen. It is done to create the more realistic 3-D characters by wearing body suits closest to the actor’s body and is very useful. If you check in terms of industrial use, this is the most extensive use of the spandex fabric.

Everything put together, we can see that the use of fabric is wide-spanning from garments to the film industry, which includes both consumer use as well as industrial use.

Now that we know spandex has broad uses let us also explore the main pros and cons of the fabric.

Pros and cons of the spandex fabric

Ever since its inception, it has been seen the popularity of spandex has been very high. But just that it is so popular does not mean the fabric has no drawbacks. Though the material’s advantages are many, some disadvantages are there too. Let us take a look at both pros and cons of this widely used fabric:

Pros of Spandex

Lightweight & Comfortable to wear

The first and foremost advantage of spandex is it is lightweight, which automatically makes it very comfortable to wear at all times and in all seasons around the year.

It is resistant to sweat

Since spandex is resistant to sweat, it can be worn in the hot and humid summers.

Highly elastic

One of the main advantages of spandex is it highly elastic. It can be stretched to almost eight times its original size. It can fit tightly on the skin and is thus often used in most sportswear, where this becomes very necessary. It can retain its original shape even if stretched to the maximum limits.

It is abrasion-resistant

Another distinct advantage of spandex is it is abrasion-resistant. It means that the fabric is durable and can be used almost anywhere at any time.

Soft, smooth, and supply

Last but not most minor benefit is that spandex is soft, smooth, and supple.

Even though the pros are many, there are some cons too. These are as follows:

Cons of Spandex

It sticks close to the body

The very reason why spandex is used so widely is also a disadvantage. Since it sticks so closely to the body, it is often a source of discomfort for its wearer.

It is sensitive to heat.

Compared to natural fibers like cotton, spandex is sensitive to heat, which is a definite drawback.

Non-Absorbent

One drawback is also the fact it is a non-absorbent material.

Not Eco-friendly

One significant drawback of spandex is it is not eco-friendly. It is so because it is artificially manufactured and does not decompose naturally, causing much pollution. It is a definite drawback when many people look for eco-friendly products and fabrics and thus prefer natural ones.

Normal question about spandex

Where is spandex fabric made?

As mentioned earlier, spandex does not have any organic component and is manufactured entirely artificially. It is manufactured by different corporations all across the globe. To name a few, Dupont is a giant corporation that has factories in dozens of other countries. But it may be localized in a particular country in particular.

Suppose you check, though; you will find that the manufacturing for spandex is located in China. In the past, the fabric was mainly produced in the United States. However, since labor costs are lower in other countries, particularly in China, much of the current spandex production happens in China.

But at the same time, it is to be noted that with a recent revival in the US manufacturing economy, some of the spandex production may shift back to the US.

What is the cost of spandex?

Apart from other factors, spandex costs are something that you might want to know about. The production of spandex is an artificial process where many steps are involved. The result is the cost of spandex is pretty high. Spandex is relatively expensive when compared to other natural fabrics and with other artificial fibers, like nylon and polyester.

But since it has broad uses, it is still bought even at higher prices.

How to wash and clean spandex garments?

If you are wondering how to clean and wash spandex garments, use the washing machine or hand wash spandex using warm water. Then, you have to tumble dry in a low-temperature setting.

Talk to our experts about the product you want to manufacture, and we’ll help you with all you need.

FAQ

What is meant by spandex fabric?

Any of various elastic textile fibers made chiefly of polyurethane also : clothing made of this material.

Is spandex fabric good for summer?

Spandex is literally not at all breathable, but it is “moisture-wicking,” which means that it won’t show sweat (even though it might help cause it).

How many types of spandex are there?

two types: Two-way Spandex can be stretched one way. (Length or Width wise) Four-way Spandex can be stretched both ways.

Is spandex a metal?

Spandex is a synthetic polymer. Chemically, it is made up of a long-chain polyglycol combined with a short diisocyanate, and contains at least 85% polyurethane.

Who created spandex?

Joseph Clois Shivers Jr. was an American textile chemist who was based in West Chester, Pennsylvania, best known for his role in the structural development of Spandex, a thermoplastic elastomer, in the 1950s.

Can spandex go in the dryer?

Spandex: Spandex does not react well to heat, and therefore putting full spandex clothing, such as a bathing suit or leggings, into the dryer will caused the fabric fibres to weaken and break.