Why use Polyester material in sports brace?

Table of Contents

What is Polyester?

Polyester is one of the most popular textiles today. You’ll find it in many applications, whether consumer products or industrial applications. In this article, you’ll learn more about polyester fibre. It is a fiber-forming polymer prepared from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG) through esterification or transesterification— Polyethylene terephthalate (PET), fibers made by spinning and post-processing.

What are the functions and characteristics of polyester fibers?

As a high-performance, low-cost chemical fiber, polyester fiber is used to make variously knitted and woven fabrics, which are widely used in sportswear, yoga clothes, outerwear, underwear, pants, down jackets, fashion, etc., in apparel products. WorldBrace manufactures customized products use high density polyester, content up to 5%-40%. With high elasticity, good resilience, abnormal smoothness, and wearing comfort. And the cloth surface is flat, soft to the touch, and has good elasticity. Very good for sports braces.

History of Polyester

The history of polyester dates back to 1926 during research on molecules and synthetic fibers. The American-based company behind the study was du Pont de Nemours and Co. W.H. Carothers led the research. Essentially, the research sought to understand what had happened to nylon, the first artificial fiber. Afterward, British researchers got interested in the earlier research by du Pont and did their study from 1939 to 1941. It is the work of the British chemists that gave birth to polyester fiber.

After this breakthrough, du Pont bought the license to produce polyester fiber in the U.S. The company decided to do more developmental work, which led to marketing the thread under a different name. It was in 1951 that they started selling it using the name Dacron. In the years that followed, a couple of companies showed interest in fiber and began producing unique versions. Currently, the primary polyester types are two and have other characteristics.

Types of Polyester Yarns

Polyester yarns are known globally, and for this reason, they are a preferred choice for many commercial manufacturers. As among the finest yarns available today, polyester yarns have characteristics that come with massive advantages. Here are the types of polyester yarns:

· Filament Yarns

Polyester filament yarns come from PET. Today’s fibre manufacturing industry makes excellent use of PET. These fibres are pretty strong. They are applicable in their monofilament and multifilament forms. Another significant characteristic of these yarns is their high level of tenacity. They are known to be quite valuable for producing lightweight fabrics like voile. The regular tenacity filament yarns come in handy in the making of undergarments. The low tenacity filament yarns are used to make products such as shirts.

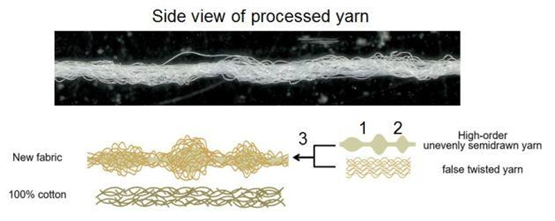

· Textured Yarns

PET multifilaments help in the making of textured yarn. They are synthetic filaments altered to add some unique texture and look.

· Spun Yarns

These are the most common yarns. They come about through the spinning of PCDT. They are also created through cut PET. One of the characteristics of spun yarns is a crumbled and bulky look. It is also important to highlight that spurn yarns look thin and smooth when under tension. They are popularly known for weaving.

How Is Polyester Fabric Made?

Making the polyester fabric involves five processes. The following is a brief discussion of each of the processes.

1.The creation of a Monomer

This is a process that requires a high level of heat. It involves the interaction between ethylene glycol and dimethyl terephthalate at high temperatures. The reaction that ensues leads to the formation of a monomer.

2.Creating a Polymer

After creating the monomer, there is a further reaction between it and dimethyl terephthalate, leading to a polymer’s formation.

3.Extruding

When the polymer is in a molten state, it is removed from the reaction chamber. It comes out in long strips that are left to cool and dry. Afterwards, they are cut into small pieces.

4.Spinning

The following process is the spinning process that involves melting the chips. Once the melting process is through, the result is a substance like honey. The importance goes through a spinneret to come up with fibres.

5.Finishing

The polyester filaments can be cut or mixed with particular chemicals to have the correct result.

How Is Polyester Fabric Used?

It is worth noting that the PET that makes the polyester fabric is still the one that makes many of the consumer products used in our daily lives. For example, it is this petroleum-based plastic that manufacturers use to make food containers and water bottles.

Regarding the fibre form, polyester comes in handy in many consumer applications. Indeed, PET is a common substitute for cotton. It also provides a viable replacement for natural fibres such as silk and wool. Manufacturers can confidently use polyester for anything customarily made from cotton material. For example, shirts and eveningwear made from cotton can also be made using polyester. Whether it’s something you want for formal or casual wear, polyester is a material you can trust for quality consumer products.

Moreover, the use of polyester is also in homeware products. Specifically, polyester, known as microfiber, is standard in kitchen and bathroom products. The softness and absorbency of the polyester fibre are characteristics with the advantages that consumers look for. Examples of these products include face towels, kitchen, and bath towels. Other products that come from polyester include rugs, blankets, and curtains.

How Much Does Polyester Fabric Cost?

It is essential to note that the price of polyester fibre keeps fluctuating. The price depends on its supply and demand. At the moment, you can buy it at around $ 1 per pound. Based on this, it’s worth noting that polyester is not an expensive textile.

Despite the changes in price that are evident quite frequently, polyester fibre is one of the most affordable textiles globally. Because of this fact, synthetic fibre continues to be extremely popular around the world.

Of course, the price has to change when a manufacturer transforms polyester into the fabric. This is where you’ll find the price changing to about $10 per yard. Those who make clothing and other consumer products buy the material and use it to make different products. It is from here that these products are packaged for the final consumer. The cost of these products depends on the product itself and the brand.

You’ll notice that the price of polyester products is lower than other fabrics. It is for this reason that polyester products are famous around the world. The affordability of fibre makes its final products affordable for many people.

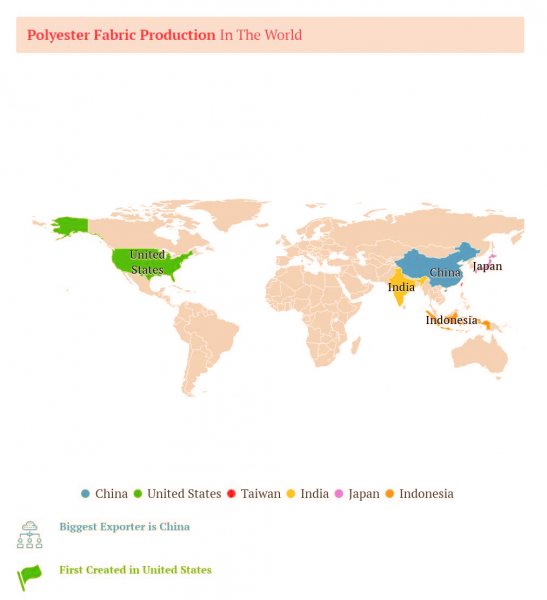

Where Is Polyester Fabric Produced?

China is a significant player in the polyester fibre industry. For a long time, China has been the largest synthetic fibre market. Other countries contribute hugely to the polyester market. The countries include Taiwan, Japan, Korea, Indonesia, and India. These countries are known to be critical producers of polyester. The United States is also regarded as a significant player in the manufacture of fibre.

As you can see, Asian countries are the largest producers of polyester fibres. After producing the fibres, the polyester stays in these Asian countries to produce consumer products. After making the consumer products, they are then exported to other countries.

What Different Types of Polyester Fabric Are There?

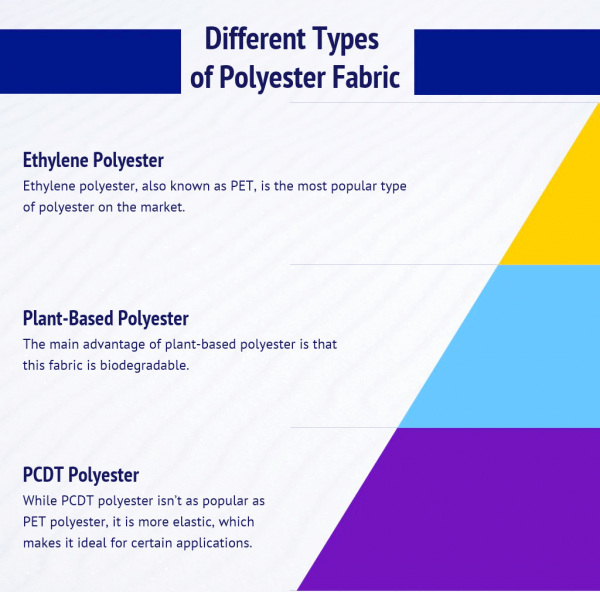

There are three types of polyester fabric.

1. Ethylene Polyester

This is the most common and popular type of polyester. It also goes by the name PET. You’ll not fail to find this type on the market.

2. Plant-Based Polyester

Just like the name suggests, this is a biodegradable fabric. This factor gives it an advantage over other types of polyester. However, it is imperative to point out that it is costly to make and it’s less durable compared to PET and the PCDT types.

3. PCDT Polyester

It is not as popular as PET. But, despite it not being a common type of polyester, it has the characteristic of being elastic. This gives it an upper hand when it comes to particular applications. It also has a higher level of durability compared to PET. For this reason, PCDT manufacturers use it for heavy applications like curtains.

Polyester Fabric Certifications Available:

There are certifications that the polyester fabric can fall under. For example, OEKO-TEX gives certificates for particular polyester textiles. Also, the Global Recycle Standard offers certification for recycled polyester. The accreditation recognizes the polyester as genuine. Other certifying organizations play a part in the accreditation of polyester. Intertek is an excellent example of such. They endorse recycled PET. For this reason, consumers can gain confidence as they use recycled polyester. These certifications are essential as they help improve the perception and image of polyester products before consumers.

Examples of Polyester Products:

There is a wide range of polyester products that consumers enjoy. These products range from apparel to heavy-duty applications. Regarding clothing fabrics, some of the products made from polyester include shirts, jackets, hats, and pants—also, home furnishing products like bedsheets, curtains, blankets, and pillowcases. Upholstered furniture is also another significant application of polyester. From the list above, it is evident that polyester is a substantial and widespread fabric today with global recognition.

Advantages:

LOWCOST:

Polyester fiber can be mass-produced at a low cost because its production cost is much lower than wool and cotton. This greatly reduces its cost and is good for consumers who to buy it.

Although polyester printing and cotton printing have certain differences in quality. However, polyester can be directly printed on it, and the price is low, which greatly reduces the cost of printing T-shirts.

Most fabrics require special lamination to be waterproof, but polyester has the advantage of being naturally waterproof. This means that the manufacturer is left with a production cost, and this advantage can also be indirectly reflected in the pricing of the product.

MOISTURE WICKING:

Polyester has the ability to absorb moisture and sweat. There are many microspores or fibril gaps and surface grooves on the fiber surface, which connect the inside and outside, so that moisture can easily enter between the fibers. At the same time, there are many tubular grooves or capillaries along the fiber axis. Moisture migration provides channels, so the fibers have good water absorption. If you wear a polyester T-shirt to your morning jog, the fabric will pull moisture from your sweat away from your skin and drain it through the polyester. After absorbing water, it will not swell due to water absorption like cotton.

HEAT-RESISTANT:

Polyester fabric is highly flame retardant, which means it takes a long time for polyester to actually catch fire. Polyester is arguably the most heat-resistant of synthetic fibers. Because it’s thermoplastic, it’s perfect for pleated skirts with long-lasting pleats. Because in the production process, repeated ironing is required to achieve the formation of wrinkles.

WEATHER-RESISTANT:

Polyester’s natural water repellency allows water to beat up on its surface but not easily penetrate.But if there is enough water on the cloth, it will eventually penetrate the fabric. But we can increase the thread count of polyester fabric in the process of making it will increase its water resistance.

Due to its weather ability, polyester is used in at least one layer of common jackets and outerwear.

UV RESISTANT:

Polyester fabrics can provide a certain degree of high UV protection. The lightfastness of polyester fabric is better than that of acrylic, and its lightfastness is better than that of natural fiber fabrics. Especially the light resistance behind the glass is very good, almost comparable to acrylic. However, as with any fabric, if you can see sunlight through it, the sunlight can reach you! It is important to take extra protective measures, such as applying sunscreen.

EASY CARE:

Polyester fabric is the most common chemical fiber clothing fabric in people’s lives. It has good wrinkle resistance and shape retention and is favored by manufacturers and customers, so it is widely used in outerwear. Polyester also has a quick-drying feature, which means you can easily hang it up to dry. At the same time, it is machine washable and will not easily deform or shrink.

Polyester is a synthetic fiber that is characterized by good elasticity, corrosion resistance, insulation, not easy to deform, and easy to wash and dry. It’s highly wrinkle-resistant, so you can wear it all day without looking sloppy at dinner time. Finally, it is highly stained resistant as it does not easily absorb liquids.

Disadvantages:

Lack of Breathability:

According to the survey report, users said that the biggest problem with polyester is the lack of breathability. The fundamental reason is that the polyester fibers of plastic are not conducive to airflow. Many people prefer natural loose cotton fabrics that are more breathable.

Lack of Moisture Absorption:

While polyester does absorb a small amount of moisture, its lack of breathability means it cannot absorb sweat from human skin. Polyester often clings to sweaty skin on hot or humid days.

Most sportswear, including WorldBraces products, use poly compounds to avoid this problem. Polycotton combines the moisture-wicking power of polyester with the breathability of the cotton. Thus reducing the stickiness of 100% polyester and the dampness of 100% cotton.

Environmental Concerns:

Environmentally conscious consumers list many valid concerns about the dangers of polyester.

One of them points out that the polyester production process involves a lot of energy and affects greenhouse gases. Also, any product made from fossil fuels is not sustainable. This shows that polyester is also not biodegradable. Some studies have shown that low-quality polyester fabrics do not degrade even after 50 years!

Second, easy-to-produce polyesters promote fast fashion to some extent, which increases the problem of fashion waste. Let’s imagine how many people will buy a low-priced garment and stop using it the next year.

Flammability:

Although polyester has a high flash point, it actually melts more easily than people think and can cause serious injury. If the polyester melts and comes into contact with your skin, it actually merges with your skin, requiring professional medical emergency treatment.

Supply Questions:

The short-term polyester market has been greatly affected by the epidemic this year. However, as the epidemic eases, the short-term polyester market has gradually returned to normal production. Currently, construction has started to maintain high-load operation, and the plants that were delayed in the first half of the year will also be put into operation one after another. The supply pressure will be in the second half of the year. Not to be underestimated.

From the downstream point of view, although the market demand for pure polyester yarn has picked up compared with the previous period, the overall situation has not completely improved. The export of anti-dumping investigation has caused the domestic export of pure polyester single yarn to decline. From this point of view, there is a lot of internal and external pressure on the spinning mills in the second half of the year.

Holds odours:

Because polyester lacks breathability, this fabric can retain odours. On the other hand, it is also tricky to remove grease and oil stains from polyester if the fabric is soiled.

Comfort Issues:

Because polyester lacks breathability, it will affect comfort to a certain extent. In addition to this, people have complained that polyester is prone to static problems because it can hold a static charge (if you have long hair, you may have taken off a winter coat and watched your hair stick out of your head because it clings) jacket!). There is also pilling, which is a condition in which loose threads come off the fabric and appear on the surface of the fabric.

Health Concerns:

Polyester fabric is non-hypoallergenic. It contains chemicals that can cause hormone problems and cause skin irritation.

Talk to our experts about the product you want to manufacture, and we’ll help you with all you need.

FAQ

Can I iron polyester?

Yes. However, polyester is less resistant under high temperatures, so you must be careful to choose the type of iron setting to avoid burning it. Using a steam iron would be the first choice.

Is polyester waterproof?

Both nylon and polyester resist water, but polyester resists it better than nylon. Additionally, polyester’s water-resistant properties increase as the thread count rises. However, neither material is fully waterproof unless it’s coated with special materials.

Is Polyester Sustainable?

Polyester generally has a significant negative environmental impact during production, use, and disposal. Polyester has often been considered more sustainable from a consumer care standpoint – polyester garments last a really long time and require less water, energy, and heat for washing.